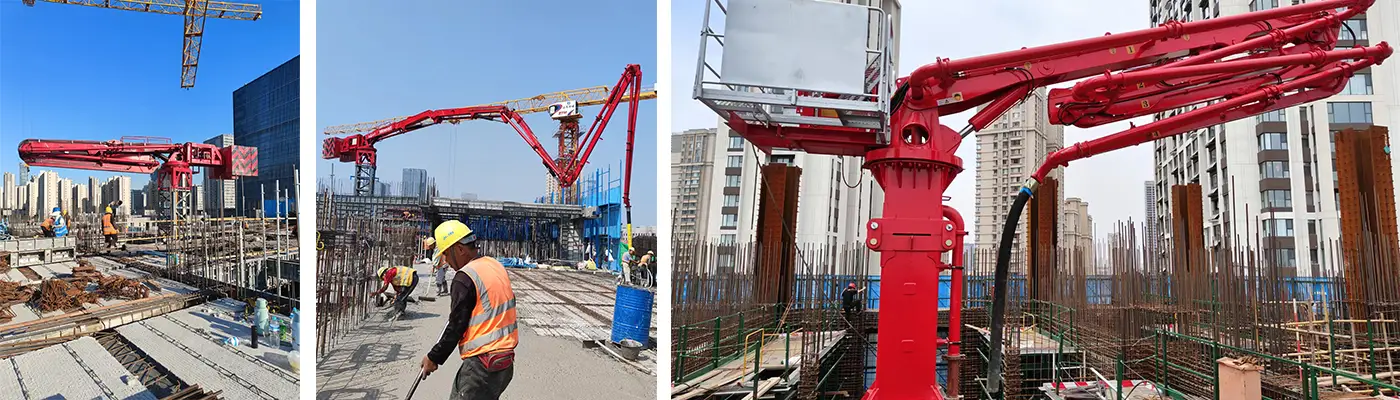

HGY TYFE Placement Boom

Category:

Product

Product Description

The advantages of hydraulic concrete placer boom mainly include the following points:

1. Safe and efficient: Hydraulic concrete placer boom can improve work efficiency and reduce labor intensity, thereby improving economic benefits.

2. Convenient and simple operation: The operation of the hydraulic concrete placer boom is simpler than that of the traditional concrete placer boom The column is climbed using hydraulic jacking. The rotation and upward movement of the boom can be controlled by the wireless remote control, making the operation more flexible and convenient.

3. High quality concrete construction: Hydraulic placing machines help improve the quality of concrete construction because it can accurately control the pouring of concrete and reduce errors.

4. Avoid hidden damage to the structure: Hydraulic concrete placer boom can reduce damage to the structure during use and protect the safety and beauty of the building.

5. Wall panel pouring and platform formwork do not interfere with each other: The hydraulic distributor can prevent wall panel pouring and platform formwork from interfering, thereby improving construction efficiency.

6. Long service life: The hydraulic concrete placer boom has strong durability and can be used for a long time without being easily damaged1.

7. Remote control operation, safe construction: The hydraulic distributor can be operated by wireless remote control, which not only improves the convenience of operation, but also ensures the safety of construction1.

8. Save labor costs: Compared with traditional distributors, hydraulic distributors can save labor costs. Most traditional distributors use horizontal arm distribution. When transporting concrete, about 3/5 people are needed to support pipes and columns, while hydraulic distributors The concrete placer boom only needs one person to operate, saving labor costs.

9. High pouring efficiency: The pouring efficiency of the hydraulic distributor is more than 3 times that of the traditional distributor, which can improve the overall construction efficiency and time management.

10. Shorten the construction period: The hydraulic distributor only needs to be installed once and can climb on its own without the need for a tower crane, effectively improving the efficiency of the tower crane on the construction site.

Technical parameters of HGY-24, 28, 30, 32 meters crawling hydraulic concrete placer boom

| project |

HGY-24D |

HGY-28D |

HGY-30 |

HGY-32 |

|

cloth radius(m) |

24 |

28 |

30 |

32 |

|

Rotation range(°) |

360° |

360° |

360° |

360° |

|

Working height(m) |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

|

Lifting height(m) |

> 3.6 |

> 3.6 |

> 3.6 |

> 3.6 |

|

Jacking speed(m/min) |

0.65 |

0.65 |

0.65 |

0.65 |

|

Swing speed(r/min) |

0.3—0.8 |

0.3-0.8 |

0.3-0.8 |

0.3-0.8 |

|

Concrete delivery pipe diameter(mm) |

φ125 |

φ125 |

φ125 |

φ125 |

|

Tail turning radius(m) |

3.52 |

3.92 |

4.4 |

4.4 |

|

hose length(m) |

3 |

3 |

3 |

3 |

|

total power(Kw) |

5.5 |

5.5 |

7.5 |

7.5 |

|

preset pressure(Mpa) |

25 |

28 |

29 |

29 |

|

Arm elevation angle(°) |

0-70 |

0-70 |

0-70 |

0-70 |

|

Tower structure and dimensions(mm) |

truss 120×1200×11500 Height can be changed according to site conditions |

truss 120×1200×11500 Height can be changed according to site conditions

|

truss 120×1200×11500 Height can be changed according to site conditions

|

truss 120×1200×11500 Height can be changed according to site conditions

|

|

Maximum weight of a single piece(Kg) |

2500 |

3800 |

3800 |

3800 |

| Hydraulic oil number |

AW46(summer) AW68(winter) |

AW46(summer) AW68(winter) |

AW46(summer) AW68(winter) |

AW46(summer) AW68(winter) |

|

Total Weight(Kg) |

10700 |

11200 |

11680 |

12000 |

|

Overall machine weight including counterweight(Kg) |

17000 |

20000 |

20280 |

20600 |

Packing and shipping

The company builds its brand with image and enters the market with its business philosophy, and takes the principle of making products seriously and providing services honestly. It has won praise in the construction of major projects at home and abroad, and has won the trust and support of users.

Case

It has a complete management method, and can give full play to team spirit, continuously innovate, and develop more energy-saving, environmentally friendly, and smarter products to serve the majority of users.

RELATED PRODUCTS

MESSAGE